Shape the future of automation and robotics! Dive into innovative projects in Industrial Automation, Robotics, and Intralogistics to join the forefront of industry advancements!

DAF and TMC use data science to reduce CO2 emissions

By 2025 newly built trucks are required to greatly reduce their CO2 emissions. Using TMC’s data science expertise DAF is working towards making its models more sustainable. One of the methods deployed is electric driving.

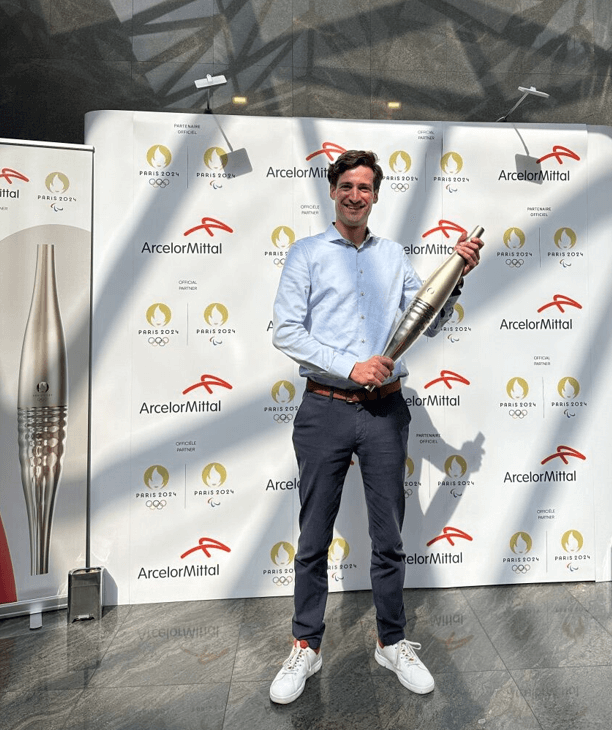

The statement by the European Commission was clear: by 2025 newly built European trucks have to reduce their CO2 emissions by 15 percent compared to 2019. And by 2030 that percentage will be raised to 30 percent. “A huge challenge,” says Willem van der Geest, data scientist at TMC who supports DAF in achieving its sustainability targets.

A number of electric trucks built by the Dutch truck manufacturer are already driving around fully operational. For their further development DAF relies in part on the knowledge and expertise of data scientists such as Van der Geest. Through the use of data DAF is seeking to improve the efficiency of these EV trucks in order to minimise energy use and maximise environmental benefits.

First time right

Through his employer, consultancy firm TMC, Van der Geest received his current assignment at DAF’s Product Development department in October 2019. “My role is to make the data DAF is collecting comprehensible for the engineers working on the development of electric trucks,” he says. Among other things the data reveals information about the use of the trucks, such as location, speed and possible engine malfunctions. Parameters like weather conditions and route information can also be included in the analyses.

Through data science DAF Product Development is pursuing two main objectives. The first is that data should enable understanding about the practical usage of the electric trucks, so they will fit perfectly with the way future customers want to use them. “This principle is called first time right,” Van der Geest says.

A practical example of a first time right analysis is an investigation into heat development in electric truck batteries. Van der Geest: “Batteries have a temperature sweet spot for their optimum performance. Your phone batteries are also empty sooner in extreme heat or cold compared to normal temperatures. That’s why it’s important to outfit electric trucks with just the right amount of cooling capacity. Data science helps by finding the right balance. Too little cooling capacity is detrimental to the efficiency of the truck, but too much is also bad since it reduces cargo capacity and volume.”

CO2 benefits

The second objective is to accelerate improvement processes. Data science helps to better understand complex processes so that labour, costs and time can be used more efficiently. Take for instance the impact of truck features like air resistance and weight on fuel use and the resulting CO2 emissions.

Van der Geest designed a statistical model that calculates these impacts very rapidly. “There are many ways to reduce CO2 emissions, for instance using lighter materials or reducing air resistance by applying spoilers. With my model DAF engineers can immediately see the CO2 benefits each separate measure will generate for newly built trucks. This enables the engineers to use their available time and resources more efficiently.” His model is a powerful feat of data science formed by modeling the data of thousands of past CO2 calculations.

Kick

As a data scientist Van der Geest previously worked for banks and insurance companies. He is enjoying his first high tech project at TMC. “I think it’s really cool that I can use my skills for a product that will benefit the environment. I feel I’m contributing something positive towards a climate neutral future. I get a real kick out of that.”

Je bent verantwoordelijk voor de dagelijkse leiding op de bouwplaats, bewaakt planning, kwaliteit, veiligheid en kosten en stuurt onderaannemers en bouwplaatsmedewerkers aan. Je bent het aanspreekpunt voor opdrachtgevers en projectteams.

Reach out for opportunities, collaborations, or questions. We're here to connect.

![tmc_jurre_v7-[3]-[0-05-57-21].jpg tmc_jurre_v7-[3]-[0-05-57-21].jpg](https://www.themembercompany.com/cache/271965b9655f503d67ca404938438f12/tmc_jurre_v7-[3]-[0-05-57-21].jpg)